Pre Engineered Steel Buildings (PEB)

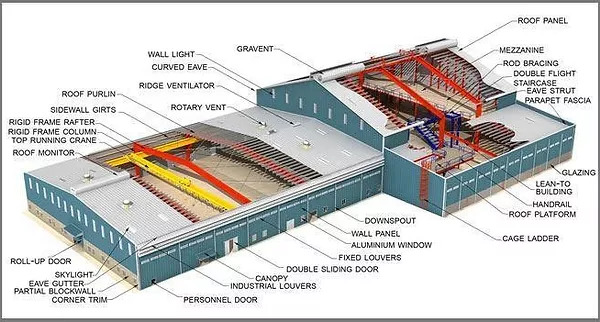

Pre-Engineered Steel Buildings (PEBs) are the latest trend in India. A PEB is a metal building that consists of light gauge metal standing seam roof panels on steel purlins spanning between rigid frames with light gauge metal wall cladding. They drastically reduce construction time. Maintenance is also extremely low. PEBs optimally utilise resources, and leverage technology to the maximum. PEBs have gained a global reputation for durability and water/earthquake resistance. PEBs are tremendously versatile – they are easy to set-up, expand, modify, and transport.

They are environment friendly and can be aesthetically designed with unique features. An estimated 20-30% can be saved on cost, as compared to conventional building methods. PEBs can be delivered to a site in just 5 to 8 weeks – conventional steel structures take as much as 20 to 25 weeks to complete. The unique techniques employed during fabrication help PEBs be up to 30% lighter than regular steel products. No welding or fabrication is required at the construction site; resulting in greater speed and efficiency.

AIE -Product Categories

- Built-up “I” section to make primary structural framing members (columns and rafters).

- Cold-formed “Z” &“C” sections to make secondary structural members(roof purlins, eaves & wall girts).

- Roll formed profiled sheeting (roof and wall panels)

- Optional sub-systems which includes mezzanine floors,crane runway beams, roof platforms, catwalks, etc

AIE -Pre-Engineered Steel Buildings Features.

- Very economical

- Quick delivery with express installation

- Low maintenance

- Wide spans and high eave heights

- Design and architectural flexibility

- High quality

- Easy to expand

- Single source responsibility

- Fast quotation along with proposal renderings

- Environment friendly

- Energy efficient.

- Water and earthquake resistant.

AIE -Product Categories

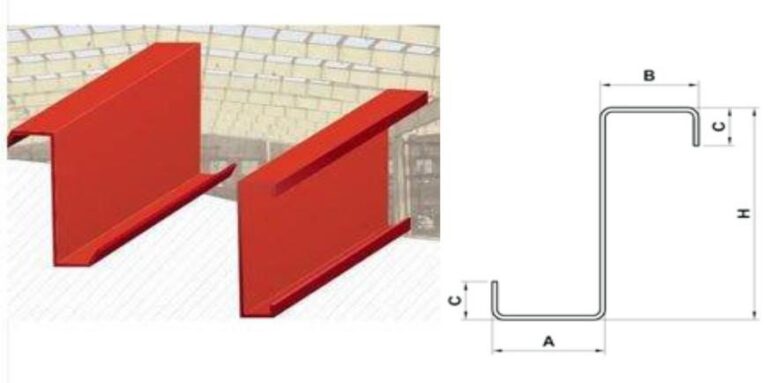

Built-up “I” section to make primary structural framing members (columns and rafters).

The most common primary framing systems are shown below…

- All these members are manufactured using high-strength grade plates, which are cut to the required size and shape.

- Intermediate Frames

- End Wall Frames

- Wind Bracing

- Crane Brackets

- Clear Span Sketch

- Beam Column Sketch

- Multi Gable Sketch

- T-Canopy Sketch

- L-Canopy Sketch

- Cantilevered Fascia Sketch

- Roof Monitor Sketch

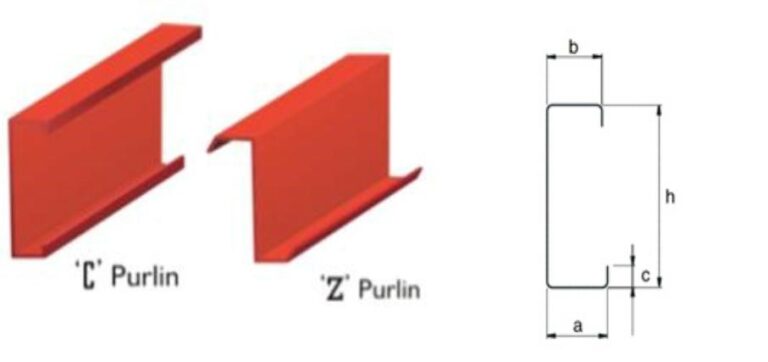

- Cold-formed“Z” &“C” sections to make secondary structural members (roof Purlins,eaves,Wall Girts)

AIE - Z-Purlins

-

‘Z’ section are manufactured by cold roll forming having a guaranteed minimum yield strength of 245 Mpa to 350 Mpa and a Z275 or 120 Galvanized coating (Optional).

AIE - C-Purlins

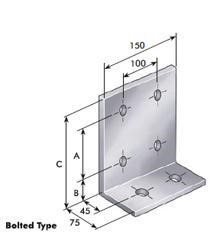

AIE - Purlin Cleats

Purlins,girts and eave struts are cold formed steel members which have a minimum yield strength of 36,000 psi(250 Mpa)

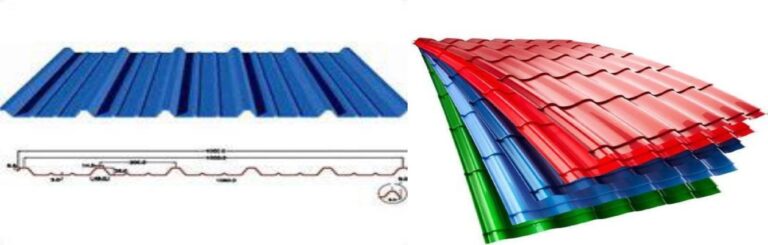

Roll formed profiled sheeting (roof and wall panels)

AIE -Coated Steel Sheet Products.

Coated steel sheet products have many attributes that make them suitable for diverse use in construction industry. These pre-painted steel sheets and coated wall panels provides a combination of strength formability, jointability, printability and economy. These Galvalume sheets provide excellent resistance to corrosion and hence has become the most preferred material for a wide range of construction uses, particularly roofing and walling.

AIE -Colour Coated Galvalume sheets

makes a unique building material. Coated steel sheets makes a unique building material. These colour coated metal sheets combines the strength of steel with corrosion protection of zinc or zinc/aluminum alloy coatings. These colour coated sheets can be punched, pressed, roll-formed and joined into a number of structural and decorative building components.

Features of AIE- Colour Coated Galvalume sheets.

- Excellent design & secure fastening systems ensure the security and weather-light performance of coated steel roofing during extreme weather.

- Coated steel sheets are resistant to fire.

- Excellent thermal properties that keep the building cooler in summer and warmer in winter

- Prevents noise and provide quite roofing system, particularly when used in combination with appropriate insulation systems.

AIE-Metal profile Crimped Sheet - (More uses than you could ever imagine).

Easy to install, crimped curved sheets provide versatility and creativity that bring new and refreshing design to industrial and domestic buildings. The combination curves and contours in concave and convex shapes with flats and angles can be used to add an aesthetic appeal to the building.

These sheets provides absolute design freedom with significant cost saving in construction. This is possible because:

- Crimped sheets require less supporting framework for parapets and roofs.

- Reduction or elimination of many flashing/capping's.

- Less cladding material required for covering a given curve.

AIE-Metal Tile Profile Sheets

Coated steel sheets make a unique building material. This colour coated steel sheets combines the strength of steel with corrosion protection of zinc or zinc/aluminium alloy coatings. These colour coated sheets can be punched, pressed, roll-formed and joined into a number of structural and decorative building components

Features of AIE-Metal Tile Profile Sheets.

- Excellent design & secure fastening systems ensure the security and weather-light performance of coated steel roofing during extreme weather.

- Coated steel sheets are resistant to fire.

- Excellent thermal properties that keep the building cooler in summer and warmer in winter

- Prevents noise and provide quite roofing system, particularly when used in combination with appropriate insulation systems.

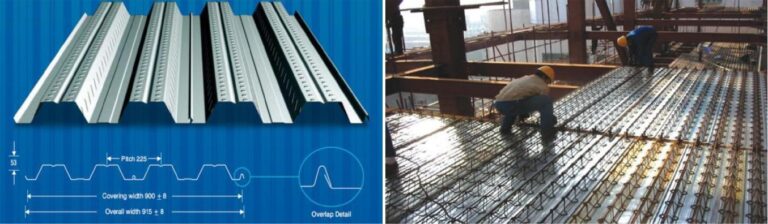

AIE -Decking Sheets

Trapezoidal Metal Profile sheets with strong and reliable shear bond performance which is augmented by cross embossing located in the profile. The composite floor profile offers the ultimate in the light weight steel decking which reduced concrete usage to provide a cost effective and alternative floor solution that easy to install.

The floor is constituted by a profiled sheet onto which a layer of concrete is poured. The sheet is bonded to the concrete by means of mouldings on the sheet which stop the concrete from slipping horizontally and detaching vertically. When the concrete is poured and until it has reached and appropriate level of hardening (stage 1), the weights of the concrete, personnel working and equipment used in borne by the sheet alone. Once the concrete has hardened (stage 2) the sheet and the concrete form a unified bond with all the characteristics of traditional reinforced concrete, where the sheet, after having performed the function of framework, acts as a metal reinforcement. Appropriate crop ends must be provided to absorb the negative moments.

Applications

- High Rise Buildings

- Multiplexes / Commercial Buildings

- Power Plant Buildings

- Office Buildings

- Mezzanine Floors in Industrial Buildings & Warehouses

- Steel floor deck for mezzanine floors

Available Finish

- Cold Rolled (CR)

- Galvanised

- Both side primer coated (Galvanised)

- Pre coated galvanized under side giving durable and attractive appearance and minimum future maintenance.

Advantages

- Reduced Concrete usage: Tensile steel for composite slab construction that cuts down on slab thickness and dead weight of buildings. Providing a more sustainable solution and reducing costs.

- No separate formwork required for slab casting.

- Reduces construction time.

- AIE Technical department offers comprahassive advisory of service on design of composite flooring should quiries arise when are not cover by this literature please contact us.

AIE -Multi-Storey Steel Buildings.

- Steel framed construction is fast gaining popularity due to relatively simple and standard designs, structural form for multi-storey buildings and great flexibility.

- AIE has emerged as one of the strongest contenders against the conventional concrete construction line, eliminating the inefficiency of the shear wall and the central portion while consolidating the support members with a much stronger material - Steel. This enables the skyscraper with both vertical and horizontal support, expediting development and is now globally accepted.

- In keeping with the current times and the global market, AIE has adapted towards the new sustainable construction methods and has mastered them with precision. Our AIE -pre-engineered light-gauge steel is being used for making new concept buildings using the new 'green material' - Steel.

- At AIE, we design modern steel framed buildings on the principle of the structure as an independent load-bearing frame, carrying both vertical and lateral loads down to the building foundations. This form of construction makes possible the creation of large column-free internal spaces which can be divided by interchangeable partitions and by eliminating the external wall as a load-bearing element, allowing the development of large window areas, curtain walling and cladding systems guaranteeing our customers the best possible experience.

Features

Key Components

The individual contributions of major components to the overall building cost can vary significantly with our building function, size and architectural treatment. However they are generally within the following ranges:

- Foundations - 5% to 10%

- Steel Skeleton - 10% to 20%

- Floor Structure - 5% to 10%

- Cladding/Finishes - 15% to 40%

- Services - 15% to 40%

Adaptability

In recent years, our endeavor has been to provide fire protection and to develop fast and efficient methods of construction; ensuring superior building services and exclusive cladding system. However, for AIE, the choice of the structural system still remains the top priority, guaranteeing a design that is coherent and successful

Versatility

Our multi-storey steel-framed buildings can adapt to a wide range of architectural styles and are in turn used for multiple purposes including:

- Office Developments

- Shopping Centres

- Car Parks

- Schools And Universities

- Hospitals And Hotels

Although the basic anatomy of each building is similar, they may have different requirements for column grid, services, and internal/external finishes. For example, a car park may be designed with floors of moderate spans and will have minimal requirements for cladding, finishes and services; whereas a prestige office development may need large column-free areas with air conditioning and under-floor cabling for computers.

Cost Efficiency

It is clear that the cost of the structure is relatively smaller compared to the total cost of the building. Consequently it is often beneficial to use a somewhat more expensive structural solution if other costs can be reduced as a result. For example, we use longer span beams in order to provide greater flexibility; and install shallow floors to facilitate service installation and reduce cladding costs. These considerations are made by our group of experts keeping in mind the projected life of the building, recognising that will often involve major refurbishment including replacement of services, fittings, and possibly envelope.

When considering the cost of the structure, we understand that it is important to recognise the weight of the material is less important than processing costs associated with the construction.

Unlike other companies, our material costs represent only 30-40 percent of the total cost of structural steelwork. The remaining 60-70 percent is accounted for in the design, detailing, fabrication, erection and protection.

Hence allowing greater standardisation, reduced fabrication costs and therefore resulting in the most economic overall system. Due to this, our unique Pre-Engineered Buildings (PEB) are witnessing higher growth compared to both Indian steel and Indian construction GDPs.

AIE-Road Over Bridges

The rapid rate of road and railways development in recent years has resulted in a massive necessity for Road Over Bridges (ROB) and Road Under Bridges (RUB). However, these structures would deter traffic on road or rail if conventional methods of construction are used. The use of steel girders saves an enormous amount of time, effort and resources. AIE has the prowess to fabricate and produce 20,000 MT of steel per annum at our sprawling 60,000 Sft. plant. The plant is fully equipped with state-of-the-art machinery and an excellent team to run it.

AIE fabricates composite steel girders from hot-dip galvanized and hot rolled structural steel. In order to fulfil the demands of discerning clients, we offer a wide range of Mild Steel plates, angles and channels that are precision engineered using a streamlined manufacturing process. Available in a variety of grades, these MS materials are known for their rust resistance and long lasting features. These grades and material are customised on the basis of our clients’ requirements in our world class facility.

Advantages

- Fabrication can be done in a work shop

- No temporary staging or speed restriction

- Light weight and hence easier, faster and safer to launch

- Super fast construction

- Easy to disassemble

- Steel girders can be reused or sold

AIE-Rob/Rub and Railways.

AIE specialises in the fabrication and erection of Composite Steel Girders for ROBs and RUBs as per specifications set by the Indian Railways. The various sectors of the Indian Railways are now coming together to make way for a more effective structure. The new structure would standardise span arrangement and design for steel composite girders to reduce time and effort.

Plant Infrastructure

- CNC plasma cutting machine

- Saw machine

- Welding manipulator

- Arc welding machines

- Pug machines

- MIG CO2 welding machines

- End milling machine

- Shear connector welding machines

- Hydraulic presses

- 4 EOT cranes in 2 bays (15T capacity each)

- Shot blasting booth

- Metalising facility

- Painting booth

Various sizes of composite steel girders fabricated by AIE.

- Flange 140 mm to 1,200 mm, Thickness 6 mm to 80 mm

- Web 180 mm To 3,000 mm, Thickness 6 mm to 60 mm

- Maximum Length 20 metres

AIE-Pre-Engineered Steel Buildings Components & Accessories.

Sliding Doors, Louvres, Windows, Personal Doors, Skylights, Wall Lights, Ridge Ventilators, Roof Jacks and Roof Curbs: Drawings / Pictures

AIE -Window

AIE -Ridge Ventilator

AIE – Ridge Ventilator is a Gravity type with bird screen and Mechanical control Damper has been practiced with Standard size of 2m long with a throat opening of 300 mm

Application :- Factories, Warehouses, Workshops, Industrial Sheds, Public utility Building etc.

AIE-Sliding Door

AIE-Roll-up Shutter

AIE- Turbo Ventilator

AIE- Polycarbonate / FRP Roof Skylight

Polycarbonate plastics with their lightweight, impact-resistant nature, offer a viable alternative to glass for skylight applications. These plastic sheets are layered with thin coatings that render them resistant to ultraviolet radiation, along with a recyclable nature, makes polycarbonate sheets a “green” component of your building. The sheets have a light-diffusing property that renders dirt undetectable; however, they can easily be cleaned by a simple pressurized jet of water. To choose the right polycarbonate sheet, you will have to consider the specific location and characteristics of your skylight.

Light transmission :- Customized light transmission to meet the specific requirements.

High impact strength :- 200 times the impact of glass and 10 times more impact resistant than FRP & Acrylic

Light weight :- Only 50 % the weight of glass. Can be easily handled.

Suitable for any kind of weather condition :- Highly durable, High resistant solid poly carbonate sheets withstand the extremities of weather – Scorching summer, torrential rain or freezing winter.

Aesthetic value :-Comes in clean or tinted, with attractive compact and textured finishes. Helps enhance the aesthetic value and the elegance of your structure.

AIE -Adjustable Louver

AIE-Insulationr

Roof Insulated Rolls :- Insulated building rolls are efficient low-density insulation material made from non–combustible glass wool fibre & bonded together by thermosetting resins. The Product is easy to handle, cut & install.

Advantages

- Keeps cool & comfortable in summer & warm in winter

- Reduction in noise by high sound absorbtion

- Non-Compustible

- Water Repellent

Reflective insulation 4 mm to 8 mm, R9 equivalant to 50 mm thk,24kg m3 Glass wool.

AIE-Ladder with Safety Cage

This Ladders with safety cage can be available as per requirement of the Building fabricated in house by us.